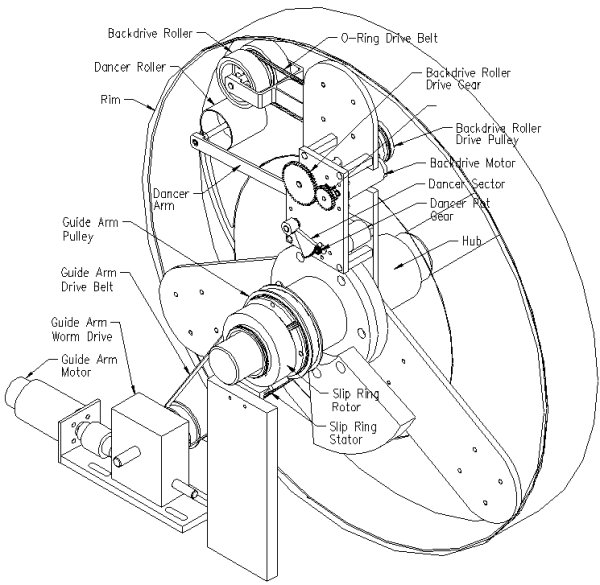

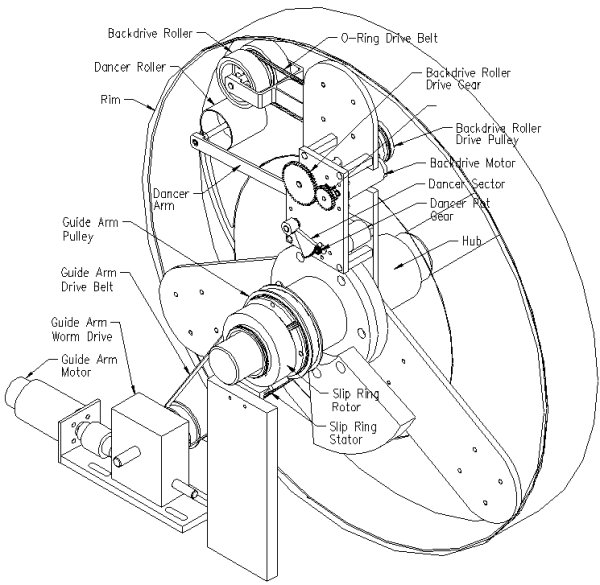

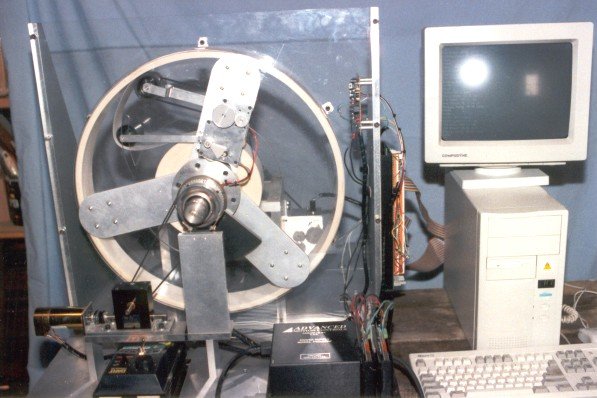

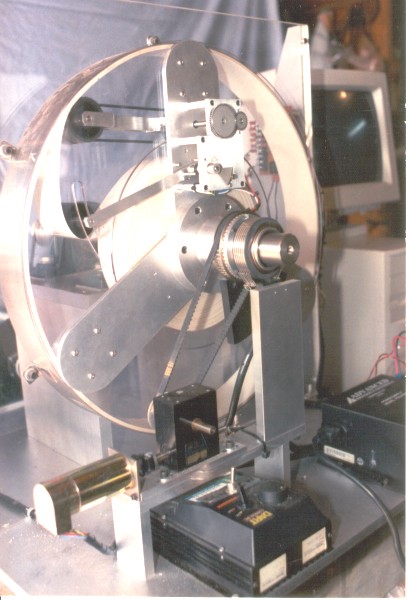

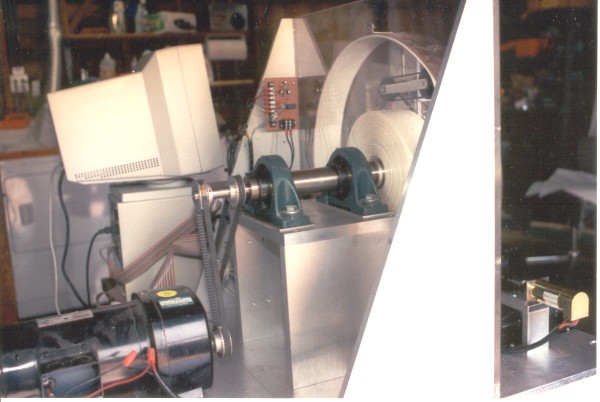

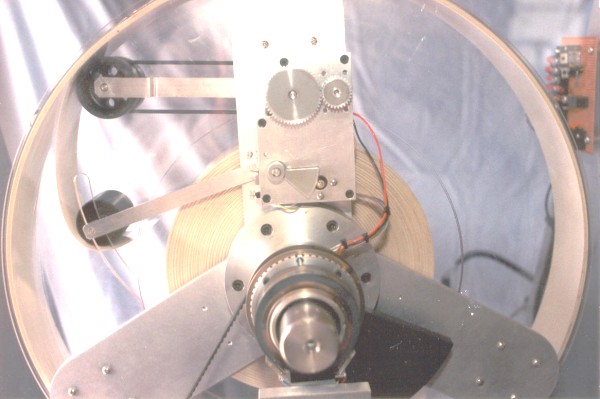

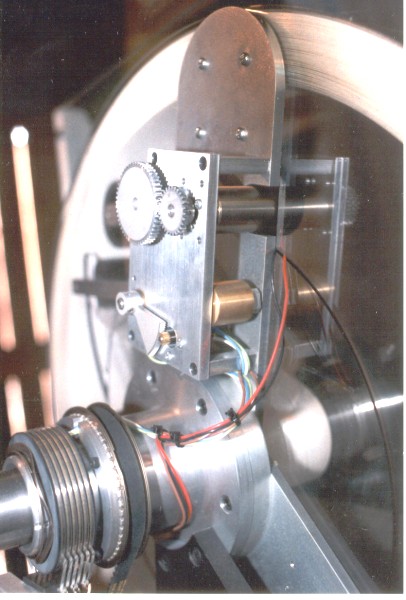

The nature and use of this prototype machine is proprietary. Basically, it winds a special tape from the central hub to the concentric outer rim, and then reverses the winding from rim to hub. It features three motors, two potentiometers, two incremental encoders, two worm-drives, belt drives, counterweight, a 6-contact electrical slip ring, a Galil 3-axis multi-tasking PC-based controller card and custom programs.

As tape comes off the Hub, a Guide Arm follows, driven by a worm-drive electric motor. Mounted on the Guide Arm is a Backdriving Roller, driven by a small Arm-mounted electric motor, which keeps the tape tightly wrapped onto the Rim.

Proper tape winding is achieved by controlling The Guide Arm speed to maintain the size of a loop of tape that is formed between the Hub and Rim. A Dancer Arm follows this Tape Loop and turns a Potentiometer, which produces a voltage signal proportional to angular displacement of the Dancer Arm. The goal of the Guide Arm control system is to maintain the Dancer Arm in the middle of its range. The Dancer Arm is displaced against a torsion return spring. This puts tension in the Tape Loop, which keeps the tape tightly wrapped on the Hub.